ACOUSTIC RESONANCE TECHNOLOGY

- Developed by Det Norske Veritas since ~1990.

- Patented and registered, licensed to BIT

- Wide bandwidth, low frequency ultrasonic pulse

- Half-wave resonance detects thickness

- Robust to moderate corrosion and sediments

- Does not require direct contact

- Detects external and internal corrosion

Acoustic Resonance Technology is a low frequency, ultra-wideband inspection technology, which enables very accurate thickness measurements to be made. BIT has developed advanced algorithms to perform ART analysis on very large amounts of data.

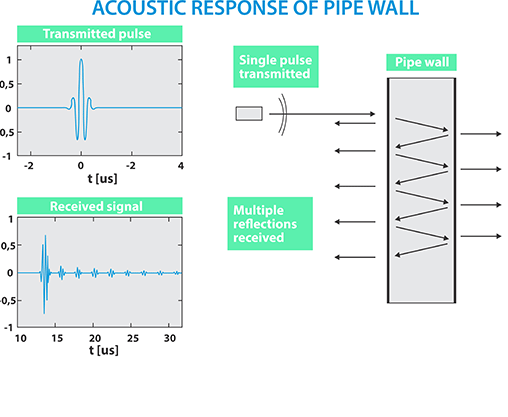

A transducer transmits a broad-band acoustic signal towards the pipe surface. The signal propagates in the pipe wall, exciting half-wave resonances. The response of the structure transmits a characteristic signal which is detected by the receiving transducer. Analysis of the frequency content of this response signal yields the resonance peak frequencies, from which the base resonance frequency, and ultimately the structure’s thickness, can be estimated.

During post-processing, multiple measurements can be combined to estimate the size and depth of flaws, such as corrosion (internal and external) on the pipe surface.

The benefits to the customers in using Acoustic Resonance Technology:

- Highly accurate wall thickness measurements

- High repeatability/consistency

- External anomaly characterisation

Challenges for Owners of Water Pipes

- High reliability demands

- Asset life hard to predict

- Limited resources

- 30-50 % water loss common

- Little knowledge of state of the network

- Huge variety of pipe types and classes

GOAL: rehabilitate with the right method at the right time at the right place