- Distinguishing production variance from corrosion

Results

Existing tools to assess the actual status of extensive water distribution networks are limited. Too often, utilities are limited to using statistics, pipe sampling and modelling to predict breakages. Modelling often leads to premature replacement of water pipes that would otherwise provide a significant remaining service lifetime. Likewise, the heterogeneity of individual pipes makes pipe sampling highly inefficient, and frequently causes weak pipes to go undetected. This approach is costly, ineffective and unsustainable.

BIT provides:

Data on the condition of every single pipe

-

Measurements of remaining thickness

-

Quantifications of corroded pipe walls

- Distinguishing external from internal corrosion

-

Map internal topography

- Presence of valves, branches, joints, repairs, etc.

-

On-board leak detection

- Matches leak noises with pipe topography

-

Recommendations for cost-effective and risk-reducing actions

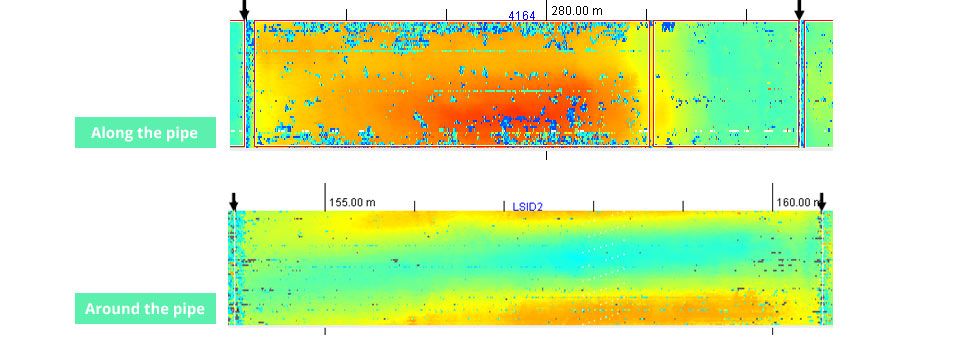

Production Variance is very common, particularly in cast iron pipes. Many casting processes are not capable of producing pipes of uniform thickness. This can result in localised thin areas with thickness values below the design standard. These areas might be missed if only spot measurements are made. Additionally, the calculated loss of thickness might be erroneous if based on the assumed original standard value. Depending on the production process, pipes might exhibit production variance along the pipe and/or around the pipe.

Heterogeneity

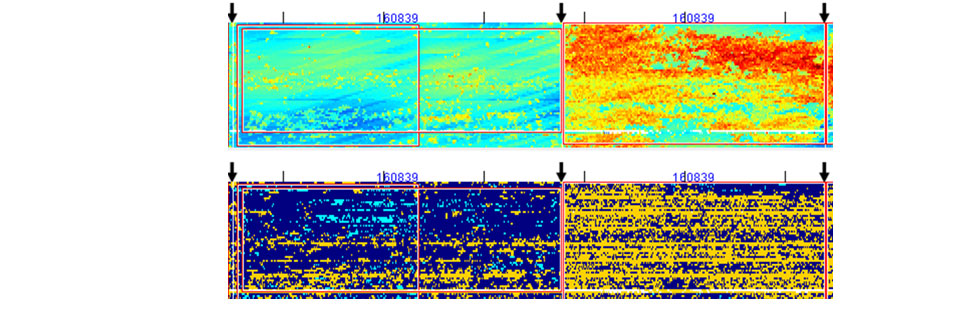

The condition of pipe segments can change considerably, from one to the next or even within the same segment. This can be related to the original state of the pipe (cf production variance) or localised phenomena such as external or internal corrosion. For this reason, spot sampling can be very unreliable.

The pipe segment on the left has heavier external corrosion on its left half. The adjacent pipe segment on the right has much heavier internal corrosion.

The report from the inspection includes:

-

Technical data on pipe and inspection

-

List of important findings

- Thickness

- Production variance for each pipe

- Internal/external corrosion

- Condition of lining

-

Analysis of the condition of each pipe

-

Summary and recommendations for actions

-

Flexible format – suitable for GIS import

The use of the BIT Report:

-

Prioritise pipes by urgency and action

- Which pipes are healthy?

- Which pipes can/should be lined?

- Which pipes should be replaced?

- Which pipes should be repaired?

- Cost/benefit/risk analysis

- Combine data with other sources/tools:

- Geographical Information Systems (GIS)

- Asset management tools

Breivoll Inspection Technologies AS is at present the only company in the world that deliver all these data without pre-cleaning the pipe and in a single scan operation.